CNC Milling Machines

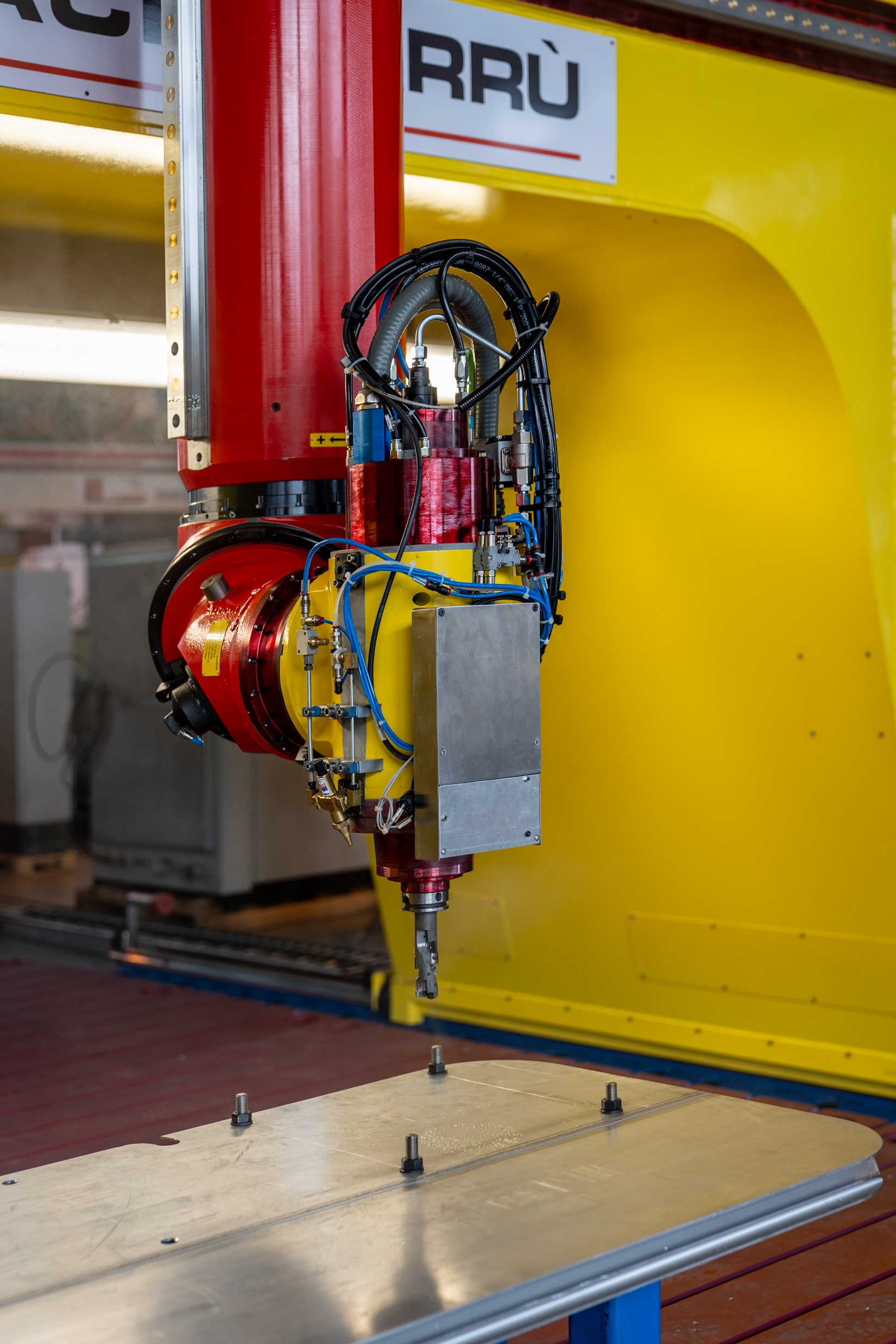

Bisiach & Carrù High-Precision Milling Machine

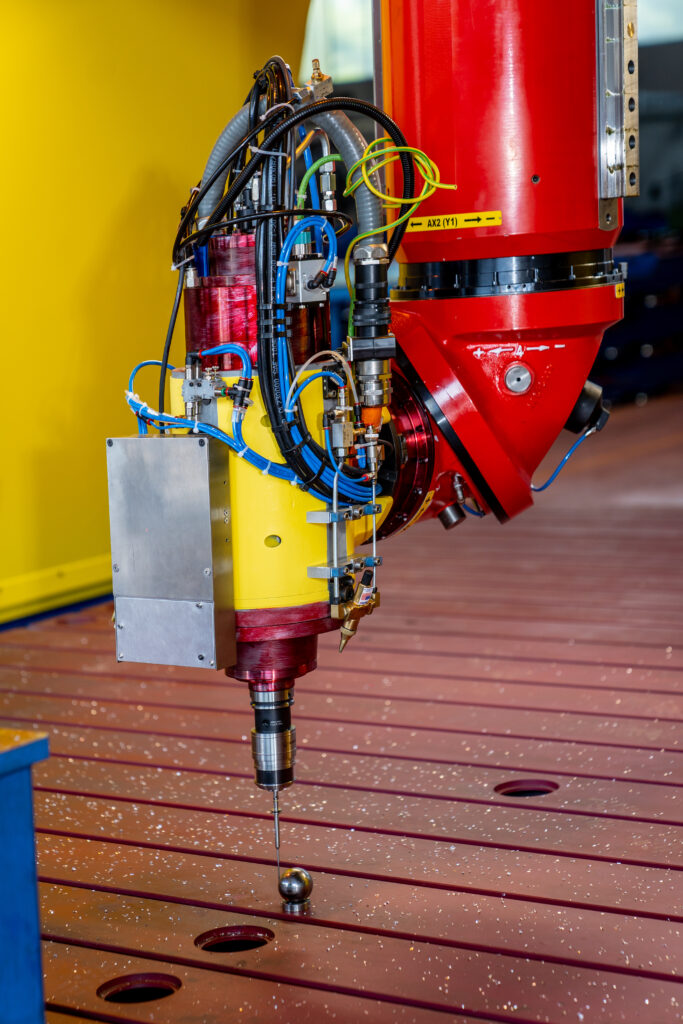

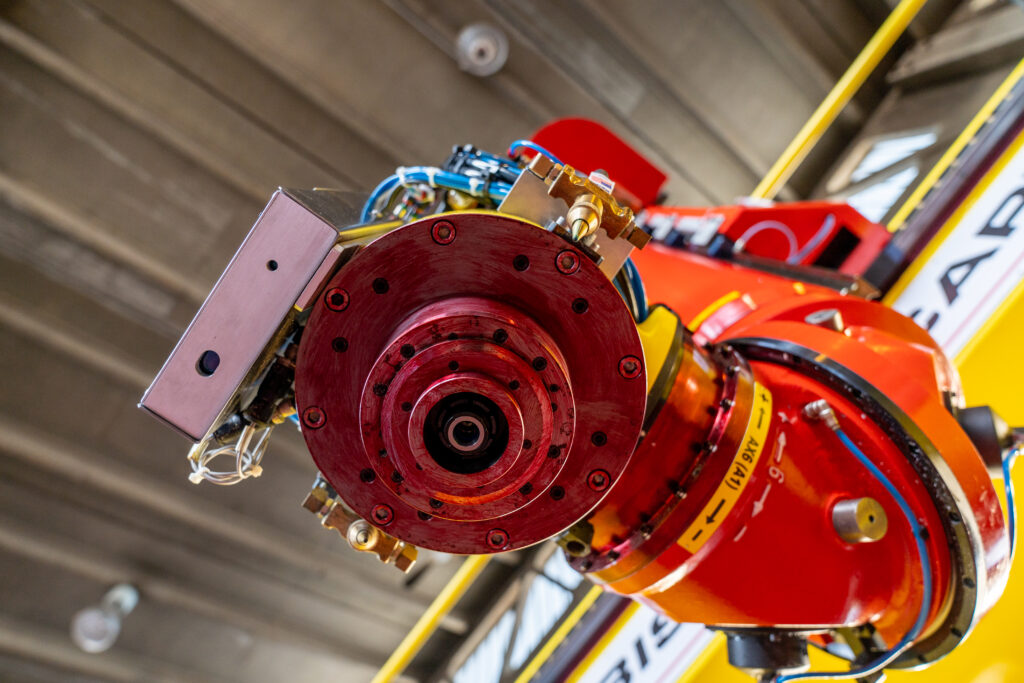

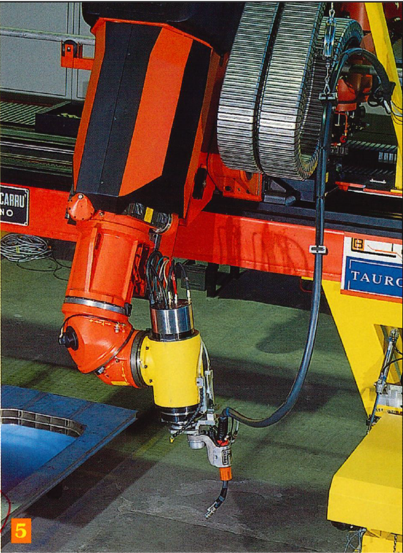

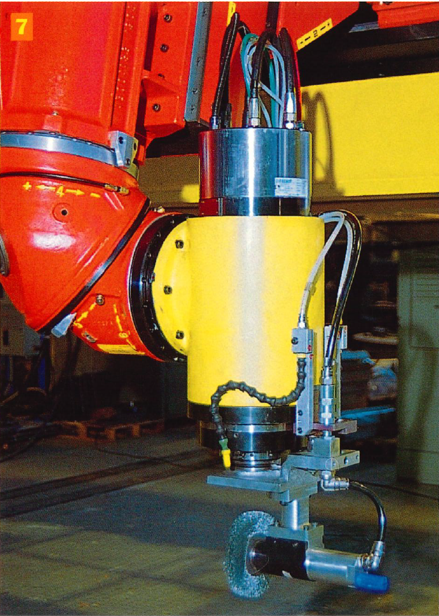

The Bisiach & Carrù CNC milling machine incorporates patented engineering solutions to enhance precision, efficiency and safety in high-performance machining.

Key Features & Advantages

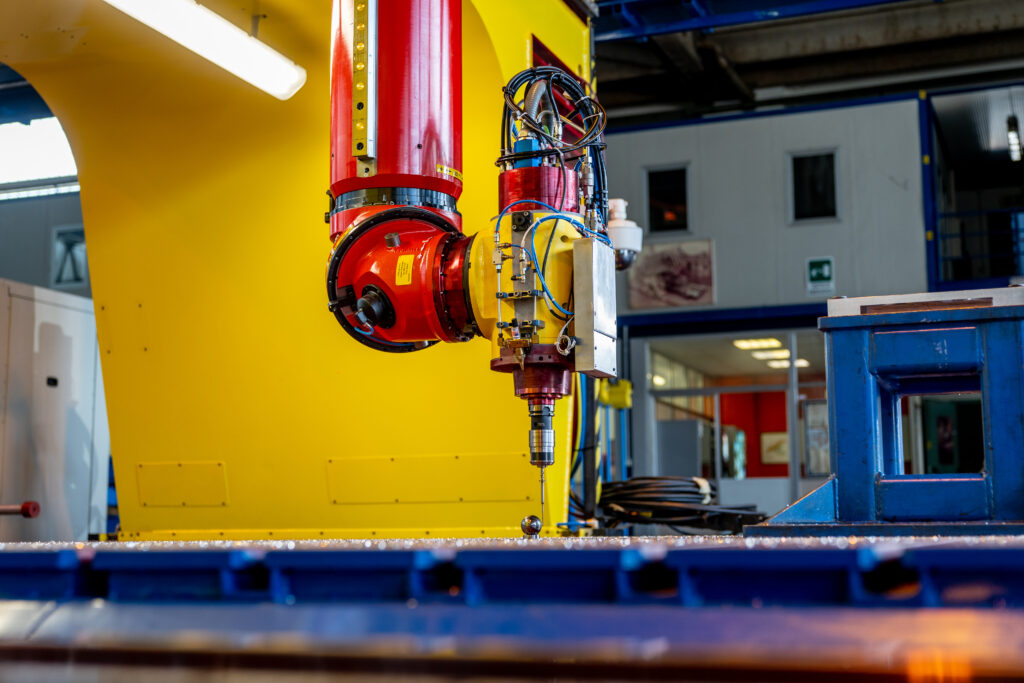

- Rigid Structural Design for Maximum Precision

- The machine’s high-rigidity frame eliminates vibrations and torsion, ensuring superior machining accuracy and surface quality.

- Lightweight, Modular Structure for Easy Transport

- The pre-assembled lightweight design enables quick reassembly, while its compact dimensions allow for cost-effective road transportation.

- Advanced Safety & Automation

- Equipped with extensive sensor technology and full automation, the machine ensures high operational safety and seamless production control.

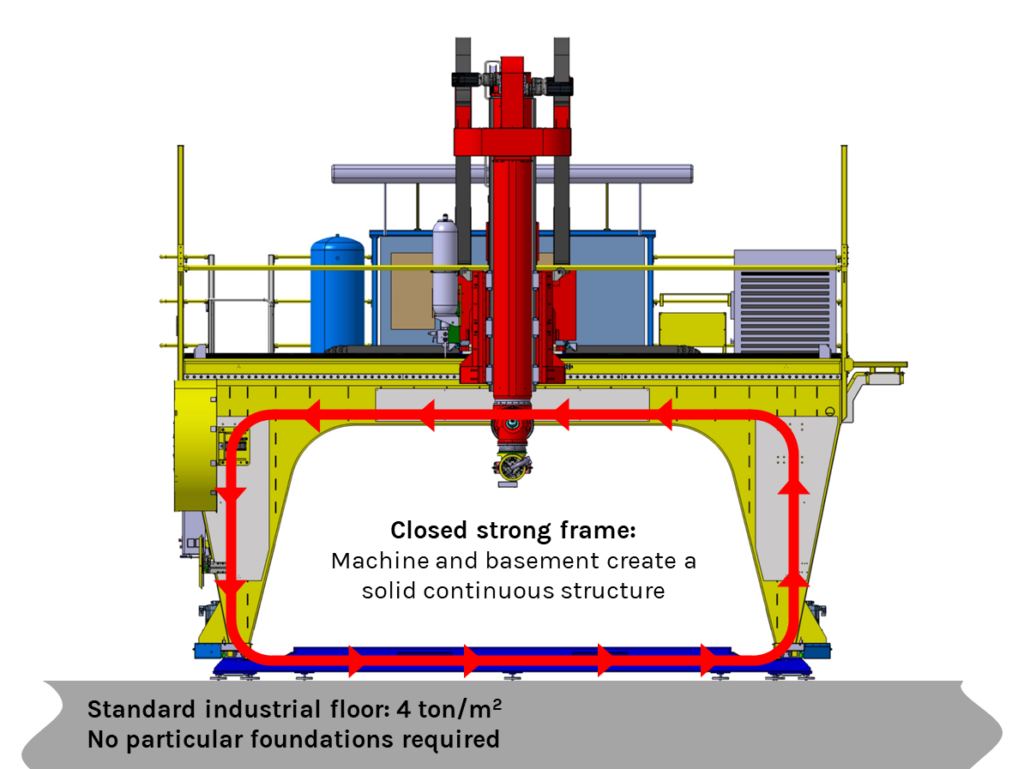

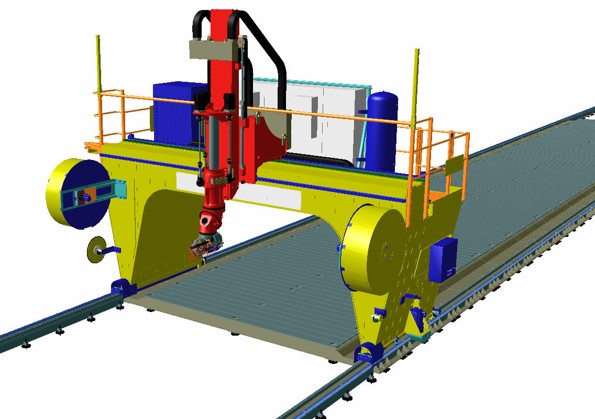

STRONG STRUCTURE – LIGHT IMPACT

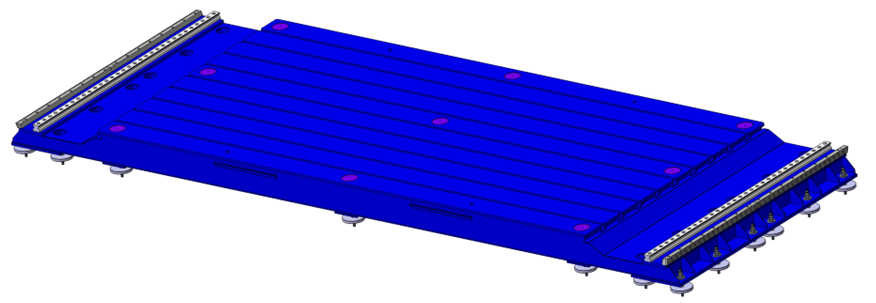

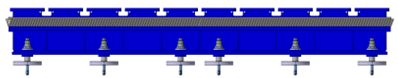

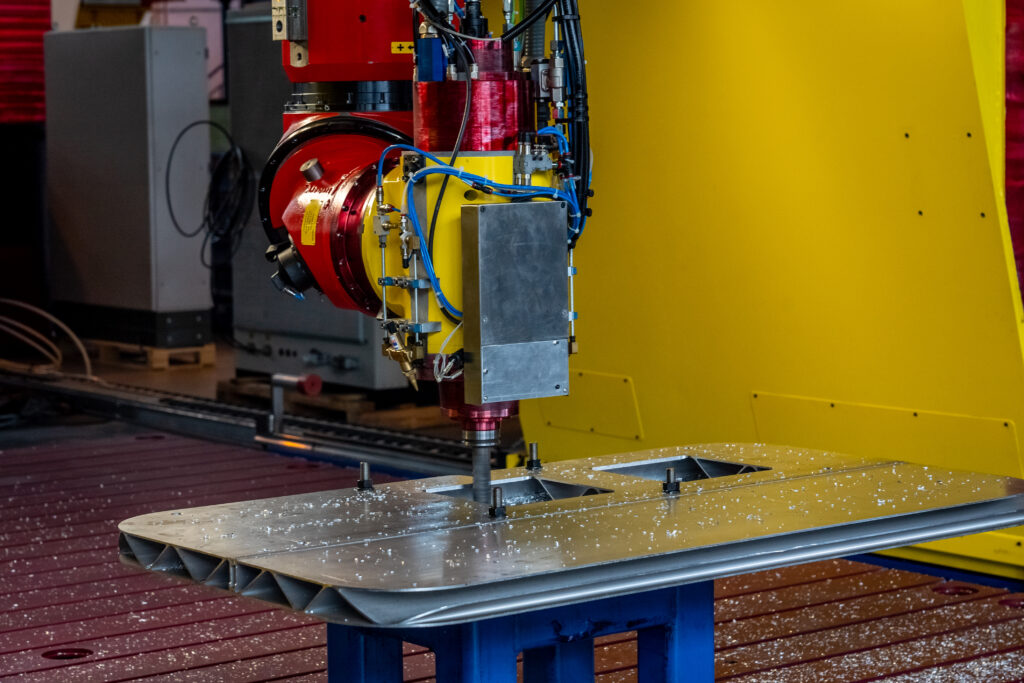

The Bisiach & Carrù milling machine is mounted on a high-precision B&C Stolle base, featuring an integrated rack and rail system for exceptional rigidity and precision.

- The monolithic gantry design eliminates torsion between the legs and the upper platform, further enhancing stability.

- The base and portal form a single, ultra-rigid structure, ensuring clean, precise, and vibration-free milling.

- Unlike conventional milling machines, this model moves on a rack system (kept clean with an air-blast mechanism) instead of wheels, guaranteeing smooth and stable movement.

- The fully automated tool change system (30+30 covered tools) enhances safety and efficiency, with real-time monitoring via integrated sensors.

MOVABLE SOUNDPROOF ARMORED CABIN

Certified Protection & Noise Reduction

Compliant with CE safety regulations, the milling machine operates within a custom-engineered soundproof cabin, designed to:

- Reduce noise levels for a safer and more comfortable work environment.

- Protect operators from flying chips and debris during milling operations.

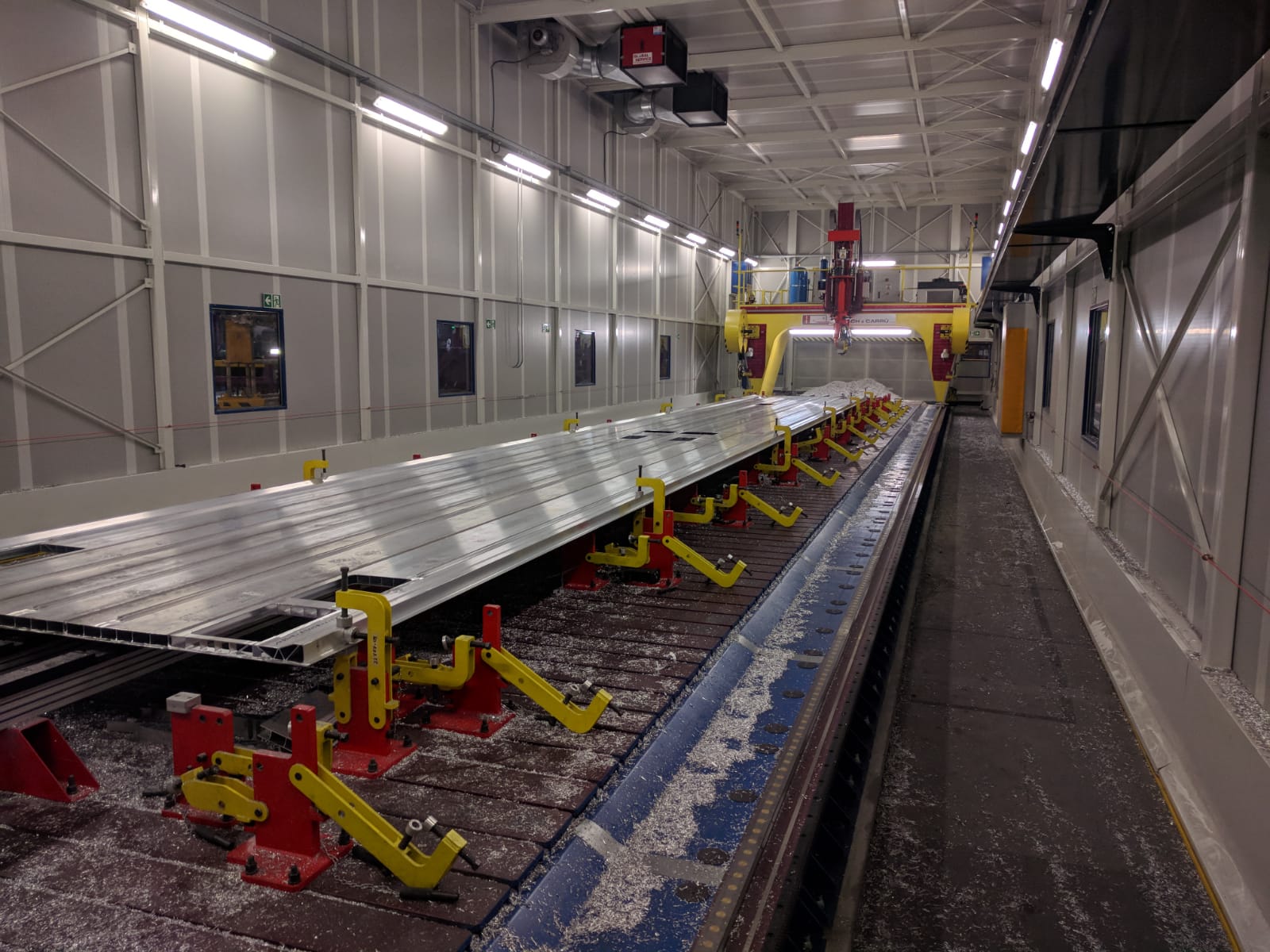

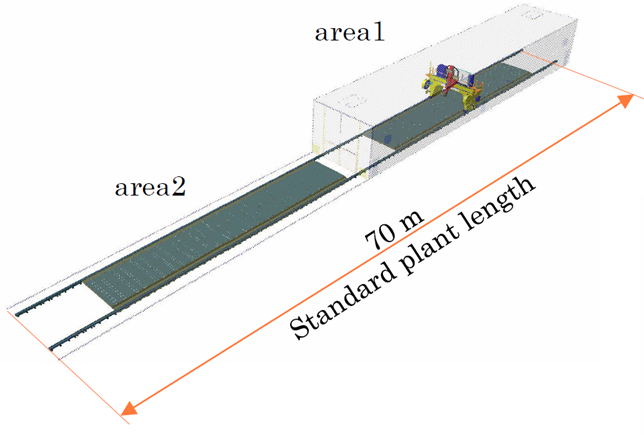

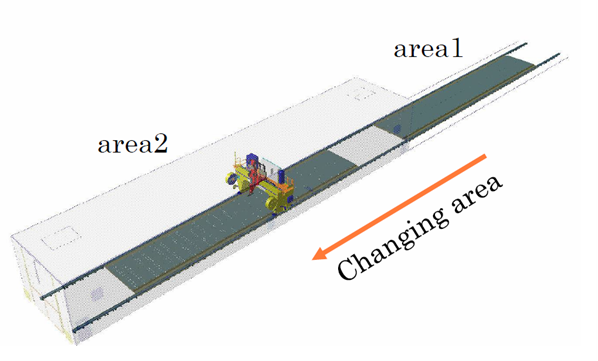

Dual-Zone Continuous Operation

The system employs a dual-area workflow to optimize productivity:

- Once machining in Area 1 is completed, the cabin and machine move together to pre-equipped Area 2, allowing uninterrupted production cycles and maximizing operational efficiency.

Why Choose Bisiach & Carrù CNC Milling Machines?

- Unmatched precision through innovative engineering.

- High-speed, vibration-free machining for superior results.

- Optimized workflow with dual-area functionality.

- State-of-the-art automation for enhanced safety and efficiency.

Contact us today to learn how Bisiach & Carrù can elevate your high-precision milling operations!

STRONG STRUCTURE – LIGHT IMPACT

The milling machine lays above a high precision B&C special Stolle basement. It integrates racks and rails in one single piece which can provide a huge amount of rigidity and precision.

The gantry has been recently redesigned in a monolithic structure, eliminating the torsions between legs and upper platform.

The basement and the portal create a single, remarkably rigid element that guarantees very precise, clean and vibration-free milling.

The fully automated change of 30+30 covered tools creates a safety zon further increased by the automatic operation and sensor technology of the entire machine.

MOVABLE SOUNDPROOF ARMORED CABIN

Cabin

According to CE regulations, the milling machine moves inside a cabin with a double purpose: soundproofing and protecting the operators from the projection of chips during milling activities. The cabin is a B&C product.