FRICTION STIR

WELDING Machines

Friction Stir Welding (FSW): High-Strength Joining Without Melting

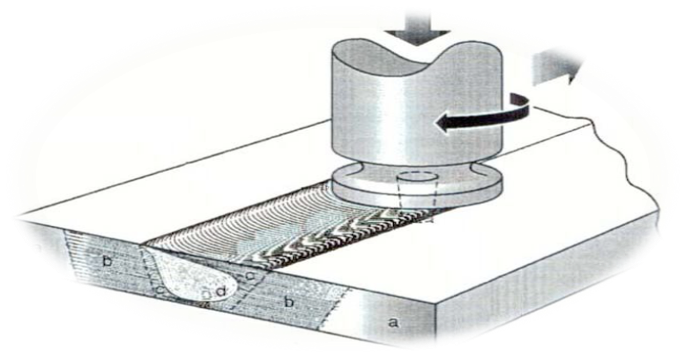

Friction Stir Welding (FSW) is an advanced welding process that joins metals without reaching their melting point. Instead, it uses a rotating tool to generate frictional heat, softening the material and allowing the tool to stir and forge the metals together along the weld joint.

One of the key advantages of FSW is that the material at the junction remains minimally affected, preserving its original mechanical properties and ensuring high structural integrity. This makes FSW ideal for applications requiring strong, defect-free welds, such as aerospace, automotive, and shipbuilding industries.