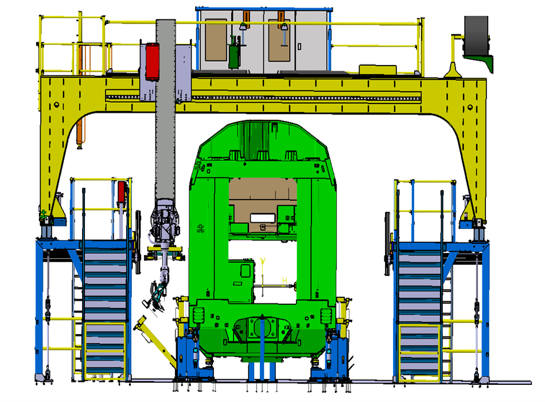

WAGON ROBOTIC

ASSEMBLY JIG

Automated Assembly & Welding Systems for Railcar Manufacturing

Bisiach & Carrù has developed a fully automated system for the assembly and welding of complete railcars, streamlining the joining of the underframe, sidewalls, and roof with unmatched precision and efficiency.

Our solution is compatible with both aluminium and stainless-steel wagons, using MIG welding and spot weldingbased on specific production requirements.

Innovative Robotic Welding Technology

At the core of our system is a high-precision gantry that moves along two lateral stands, supporting an anthropomorphic welding robot. This structure accommodates entire railcars, allowing the robot to reach every joint and weld with maximum accuracy.

The Next Evolution: Fully Integrated Welding & Milling

The upcoming revolution in technology is to use our robot and structure to weld the complete wagon (floor, sidewalls and roof) and then milling the windows and doors cutout after the railcar is already formed. Our machine is able to shift from milling to welding tool in automatic. This type of machining is perfectly feasible with our machine, thanks to the strength and the huge components dimension which is possible to weld and mill.

✔ Complete wagon welding – Seamlessly joins the floor, sidewalls, and roof in a single automated process.

✔ Integrated milling & welding – After welding, the system can automatically switch tools to perform precision cutouts for windows and doors.

✔ Heavy-duty performance – Designed to handle large, high-strength components with exceptional stability.

With Bisiach & Carrù’s automated railcar assembly solutions, manufacturers can achieve higher efficiency, superior quality and reduced production times—making the future of railcar fabrication smarter and more cost-effective.