SPOT WELDING Machines

Automated Spot Welding Solutions for Railcar Manufacturing

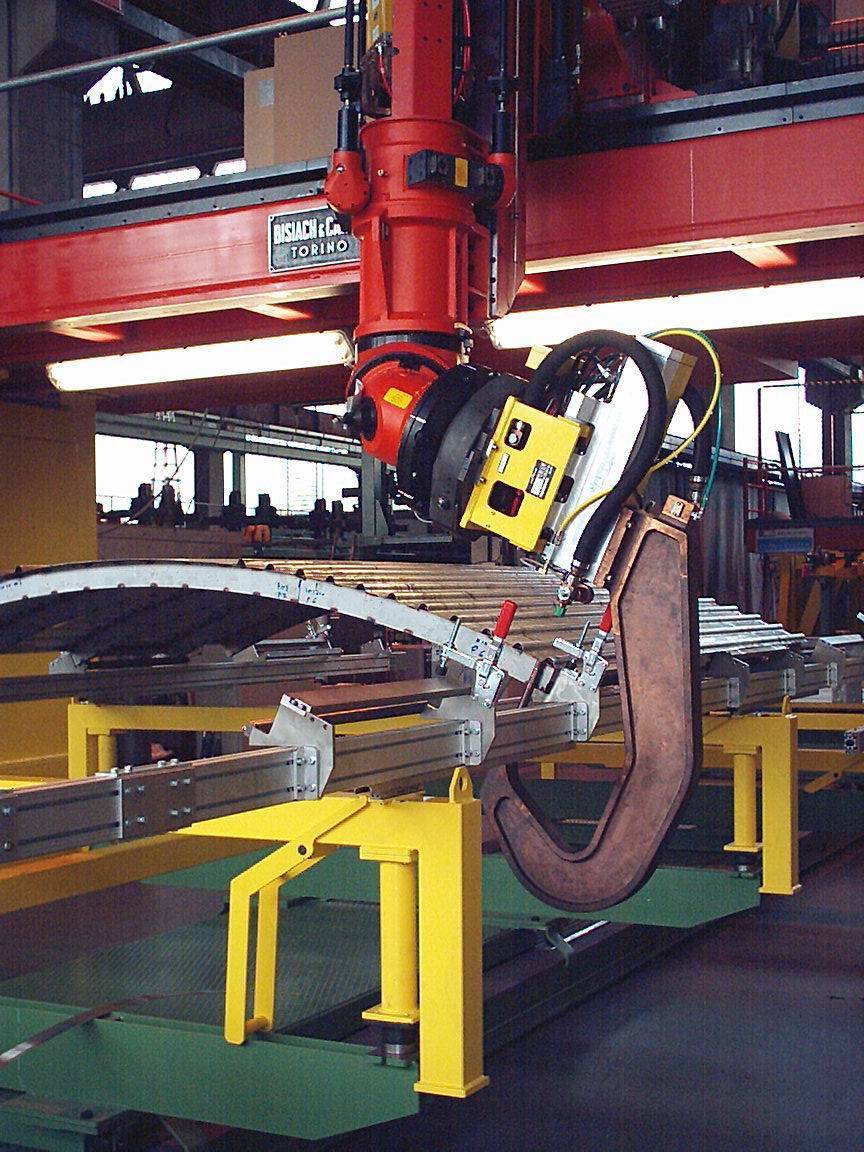

Bisiach & Carrù specializes in advanced spot welding systems designed for railway manufacturing, enabling high-precision, high-efficiency welding of large steel components.

Spot welding is a resistance welding process that joins two or more steel sheets by applying pressure and high electrical current at precise points. This technique is widely used in railcar production, where multiple welds must be performed quickly, reliably, and with minimal material distortion.

High-Precision Robotic Spot Welding Systems

Our automated spot welding machines are large-scale 6-axis gantry robots engineered for versatility and precision. These systems are capable of:

✔ Automatic welding gun change – Seamlessly switching between different gun sizes based on the welding requirements.

✔ Handling large railcar components – Our spot welding guns can accommodate clearances of up to 1.7 meters, ideal for large steel structures.

✔ Precision welding in tight spaces – Smaller, custom-designed welding guns ensure accessibility to hard-to-reach areas.

✔ Fully customized welding solutions – We design and manufacture welding guns tailored to the specific needs of railcar components.

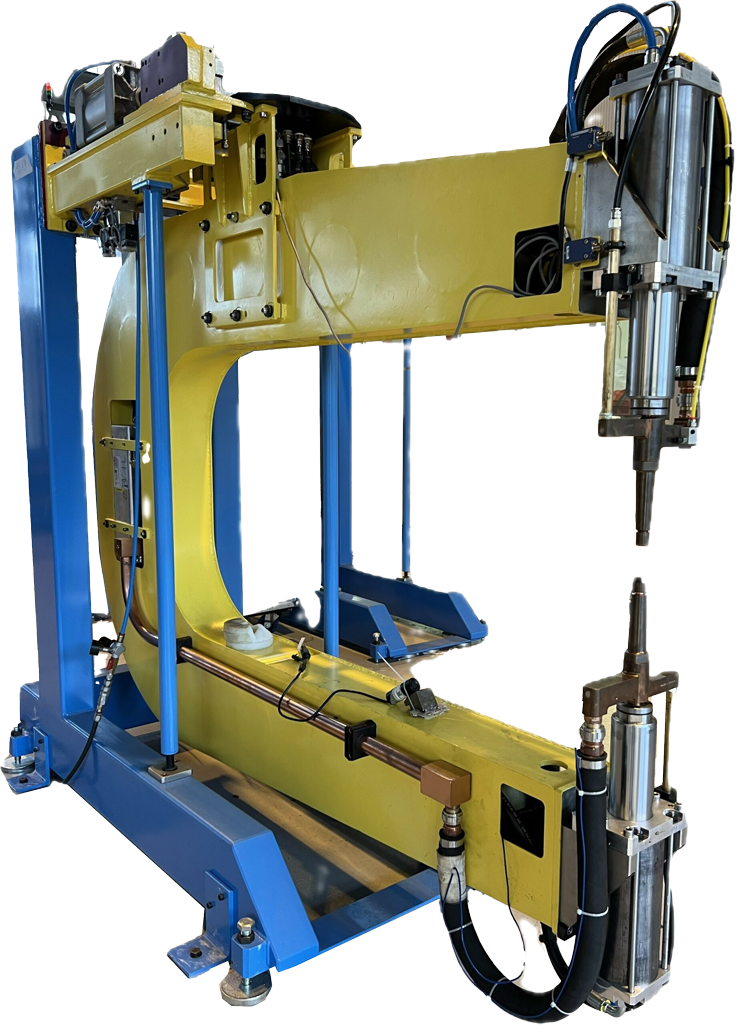

Comprehensive Spot Welding Equipment

We offer a wide range of welding tools and fixtures, including:

✔ Welding guns – Designed for high-pressure spot welding.

✔ Scissors-gun & J-gun – Adaptable tools for various welding applications.

✔ Single poke & double poke systems – Efficient for different spot welding configurations.

✔ Copper bed welding fixture – A specialized tool that uses a copper surface for optimized poke welding, ensuring fast and precise welds.

✔ Custom train component fixtures – Engineered to securely hold railcar components during welding, improving accuracy and repeatability.

Why Choose Bisiach & Carrù for Automated Spot Welding?

✔ Optimized for railway industry standards – Ensures high-strength, durable welds for railcar production.

✔ Enhanced automation – Reduces cycle times and increases production efficiency.

✔ Adaptable and scalable – Custom solutions for stainless steel and aluminum railcars.

With Bisiach & Carrù’s advanced spot welding technology, manufacturers can achieve faster production times, superior weld quality, and fully automated railcar assembly processes.