Automated Mig

Welding

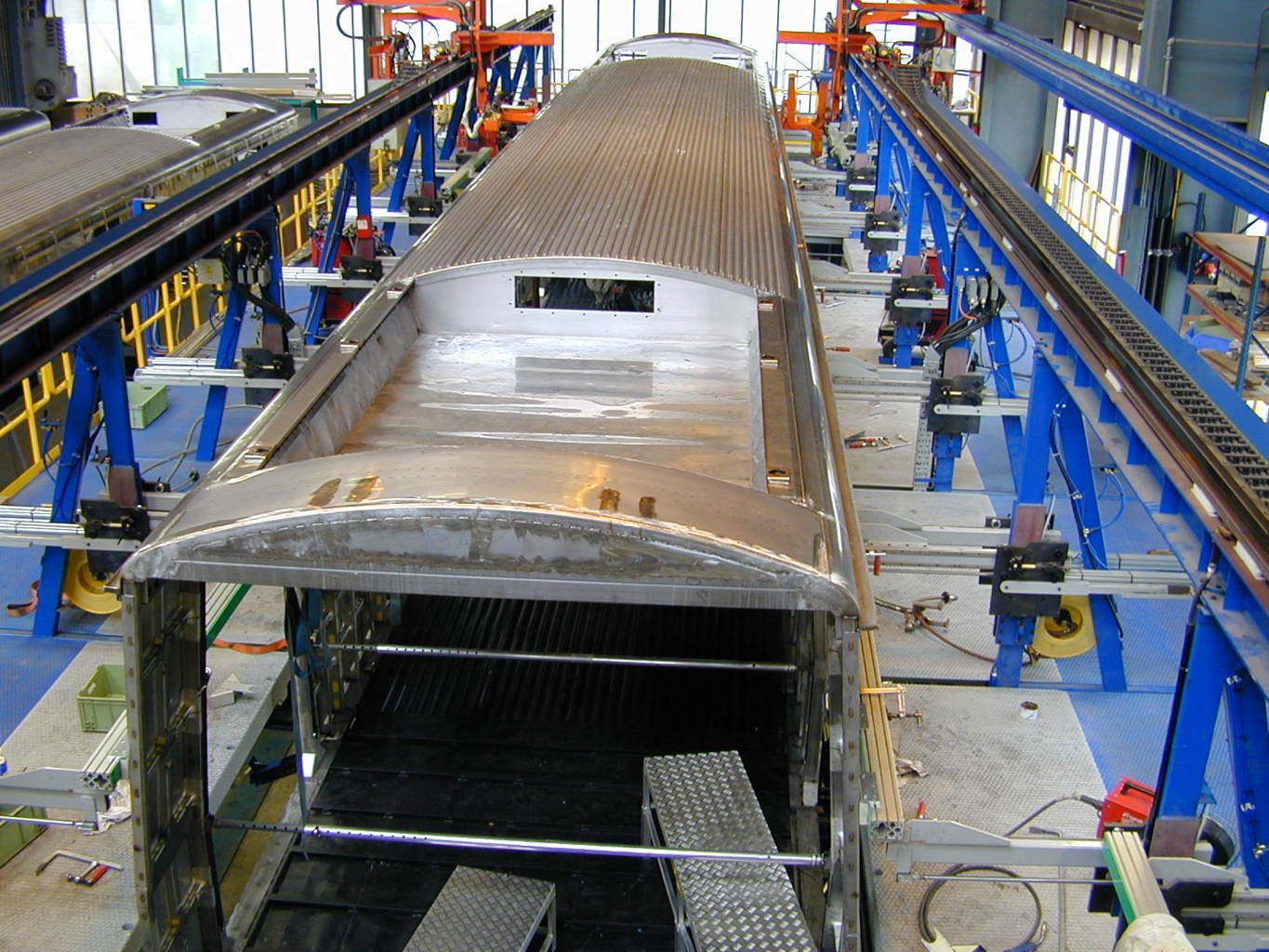

Automated MIG Welding Systems for Railcar Manufacturing

Bisiach & Carrù develops advanced MIG welding solutions designed for the automated assembly of railcars, ensuring high precision, efficiency, and reliability in large-scale railway manufacturing.

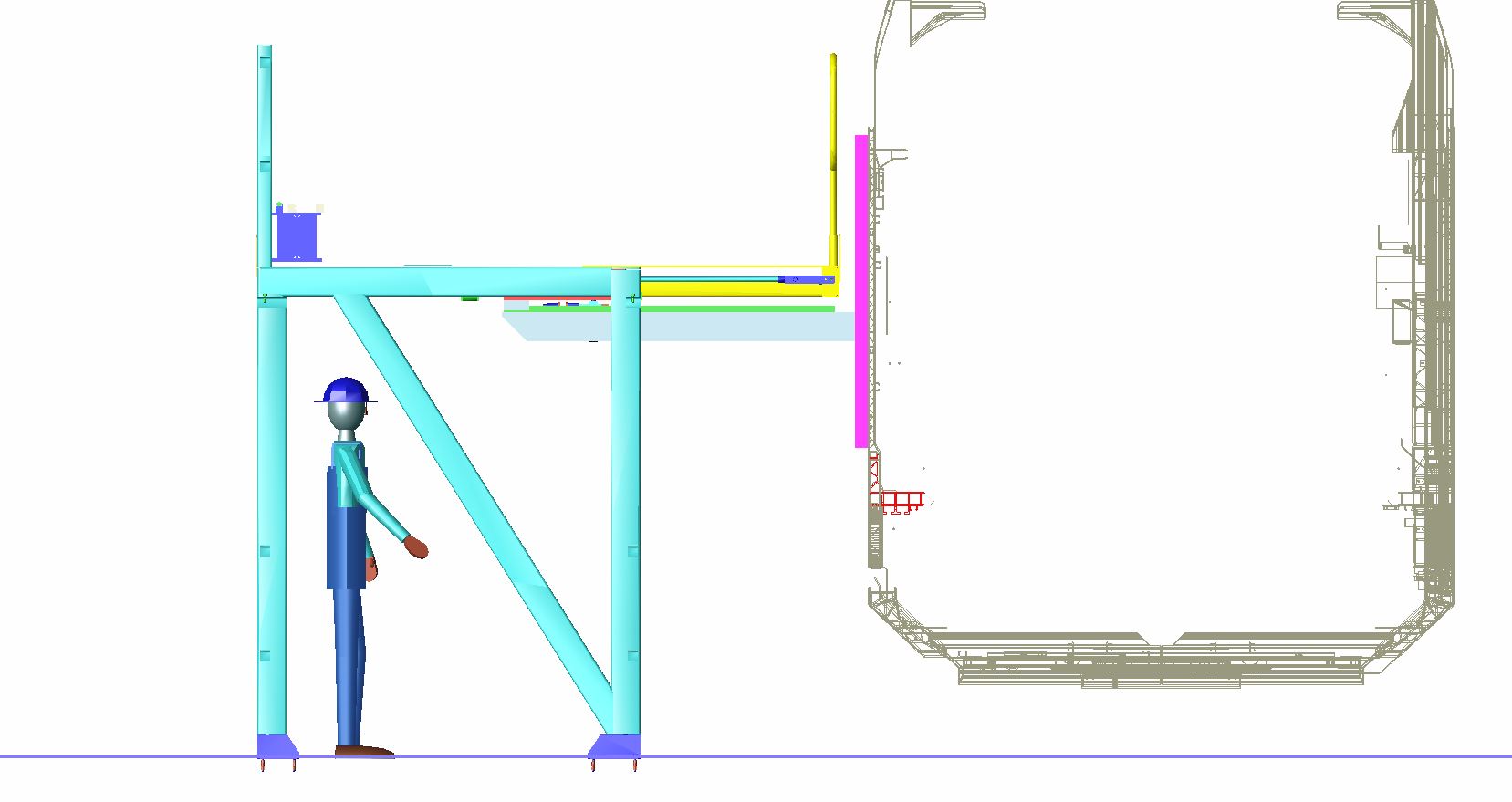

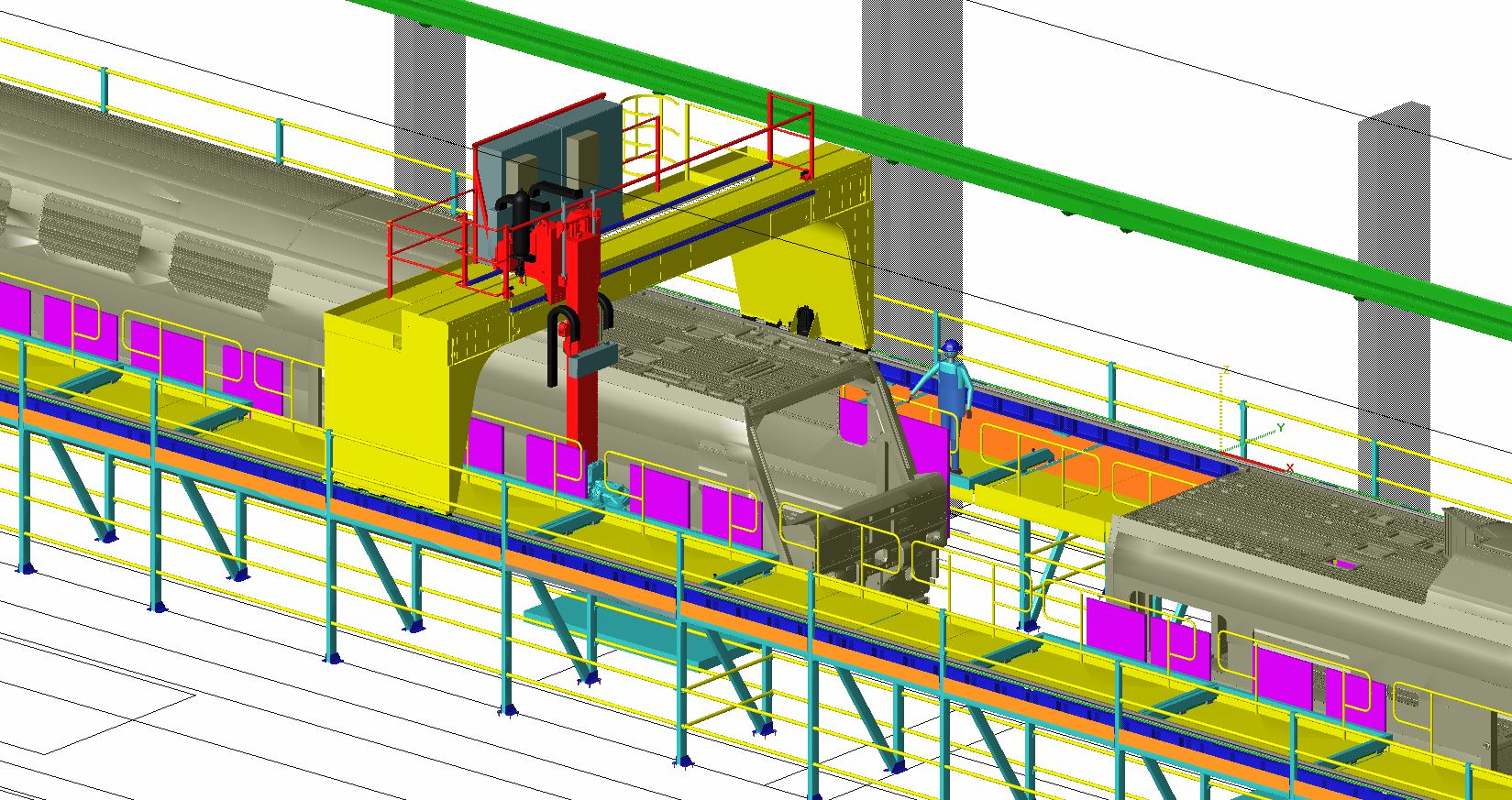

Innovative Robotic MIG Welding Technology

Our MIG welding machines are equipped with robotic arms featuring welding torches mounted on vertical slides, allowing for smooth and wide movement along high-accuracy guides. This system ensures consistent weld qualitywhile reducing cycle times and production costs.

Flexible Welding Configurations

Bisiach & Carrù offers customized MIG welding solutions based on:

✔ Gantry robots – High-precision, large-scale welding for extensive railcar structures.

✔ Anthropomorphic robotic arms – Adaptable and dynamic solutions for complex welding tasks.

Optimized for Railcar Assembly

Our automated MIG welding systems are specifically designed for:

✔ Joining the underframe with the sidewalls – Ensuring structural integrity and precision.

✔ Welding sidewalls to the roof – Providing durable and seamless connections for railcar structures.

✔ Versatile welding solutions – Suitable for stainless steel and aluminum railcar components.

Why Choose Bisiach & Carrù?

✔ Fully automated, high-precision welding systems – Minimize errors and increase productivity.

✔ Custom engineering solutions – Tailored to the specific needs of railway manufacturers.

✔ Advanced robotic technology – Improves weld quality and reduces production time.

With Bisiach & Carrù’s automated MIG welding systems, railway manufacturers can streamline production, enhance weld accuracy, and ensure high-performance railcar assembly.