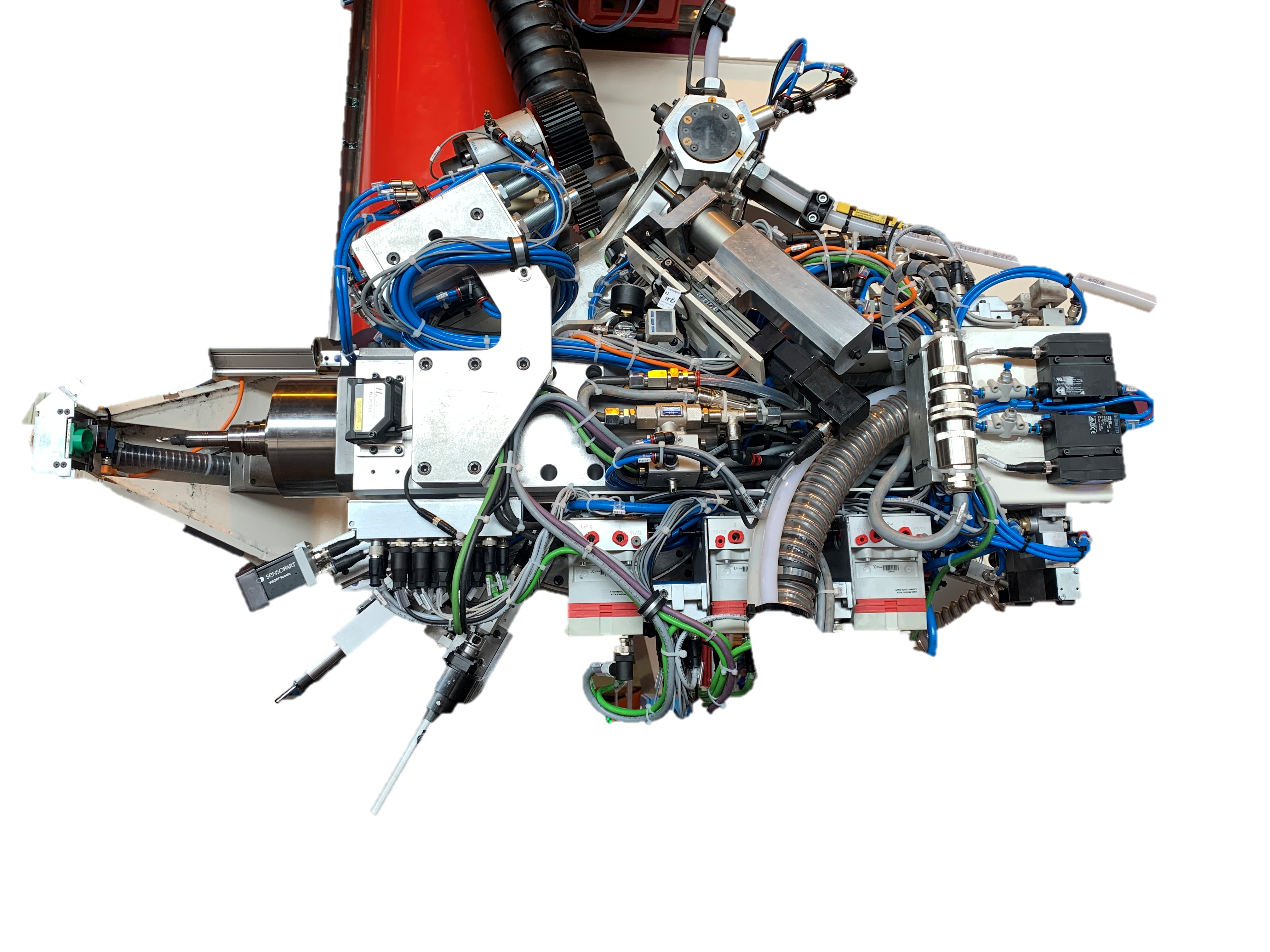

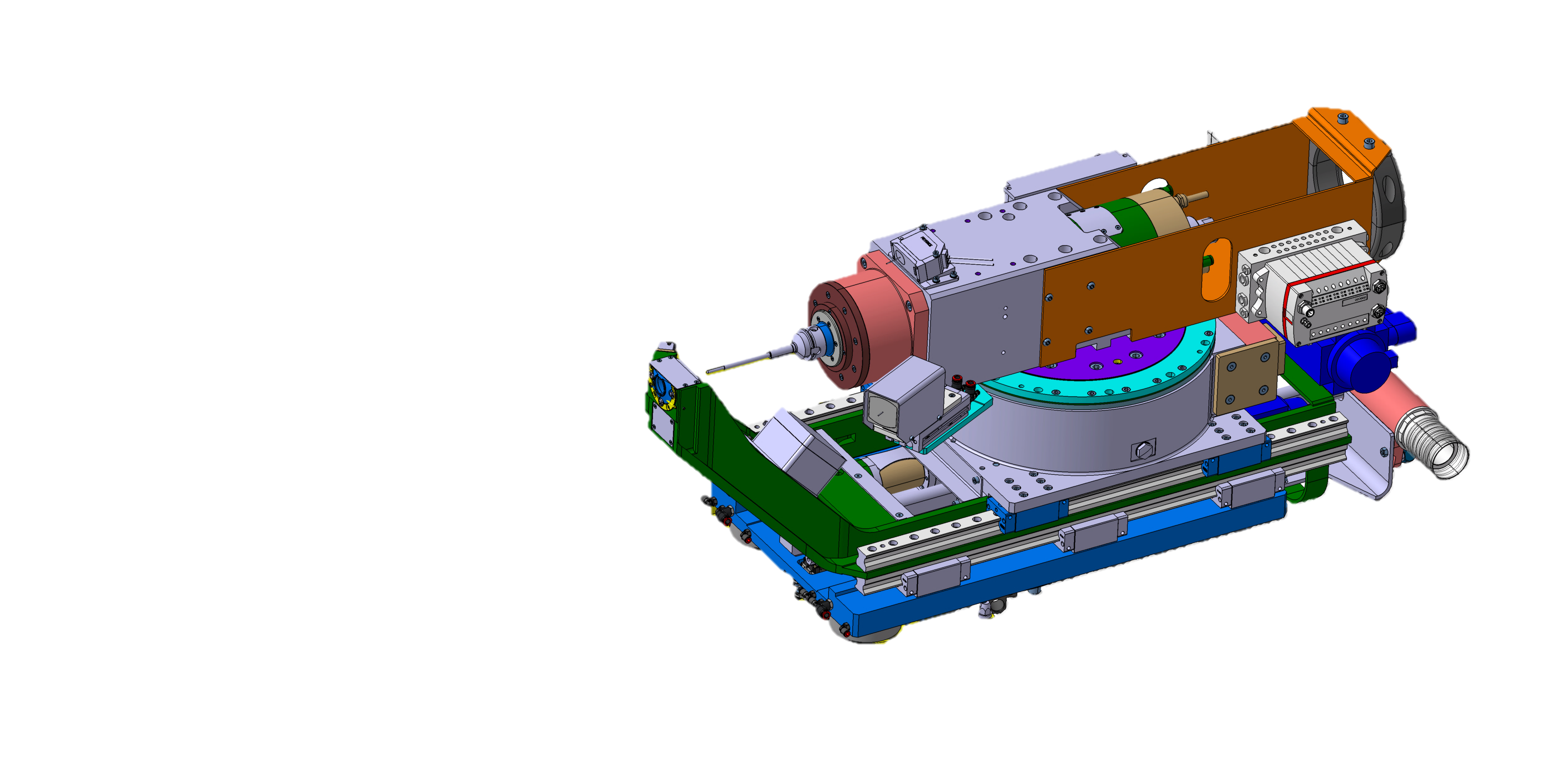

DRILLING & RIVETTING

MACHINE

- Drill&fill (CFRP, Ti, Al…)

- One-Up drilling

- Countersinking

- Peck drill

- Dry or wet installation (with or without rivet sealant)

- Element positioning

- Shim placement

- Hole measuring and automatic rivet grip selection

- Pop rivet removal

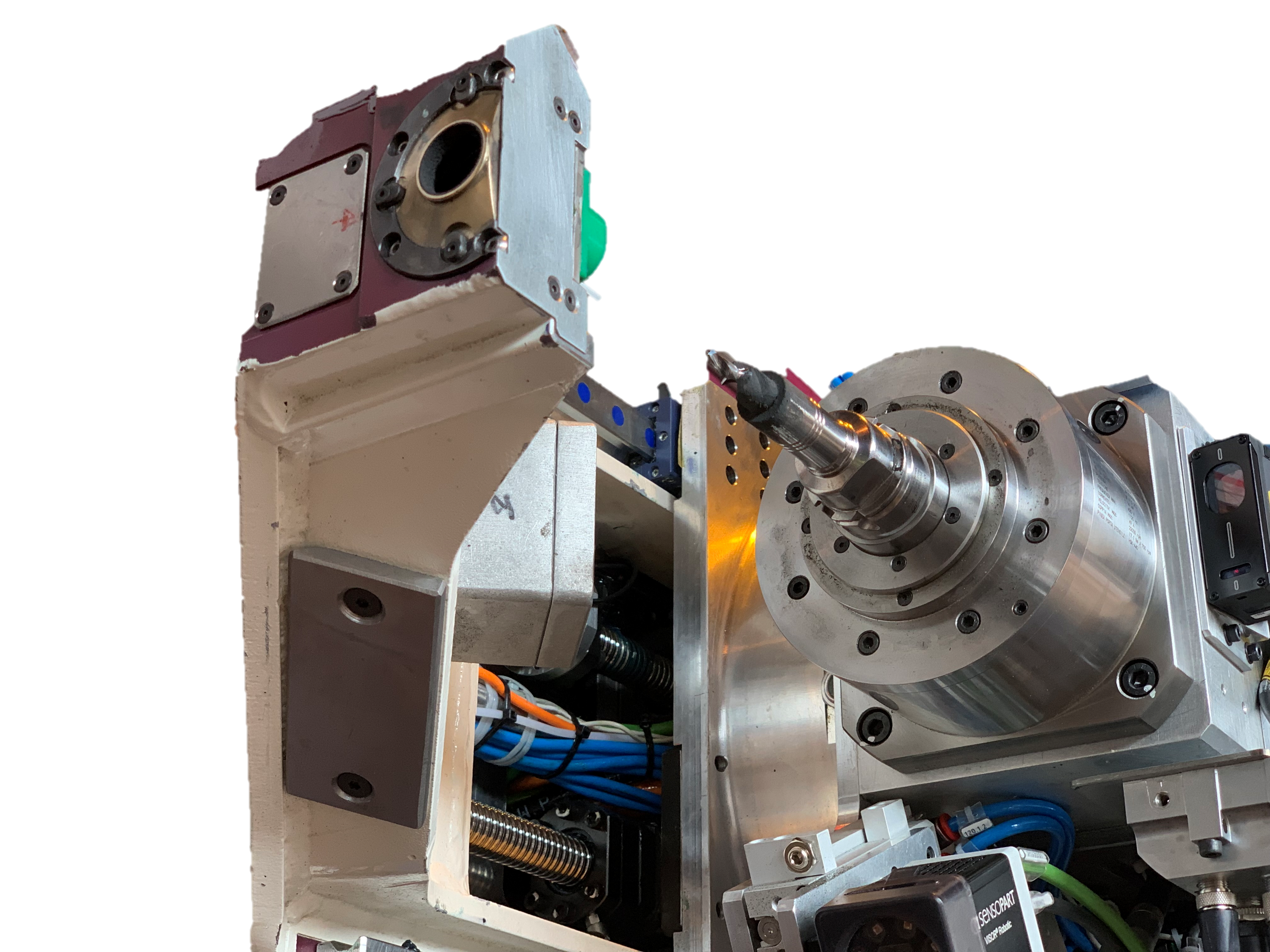

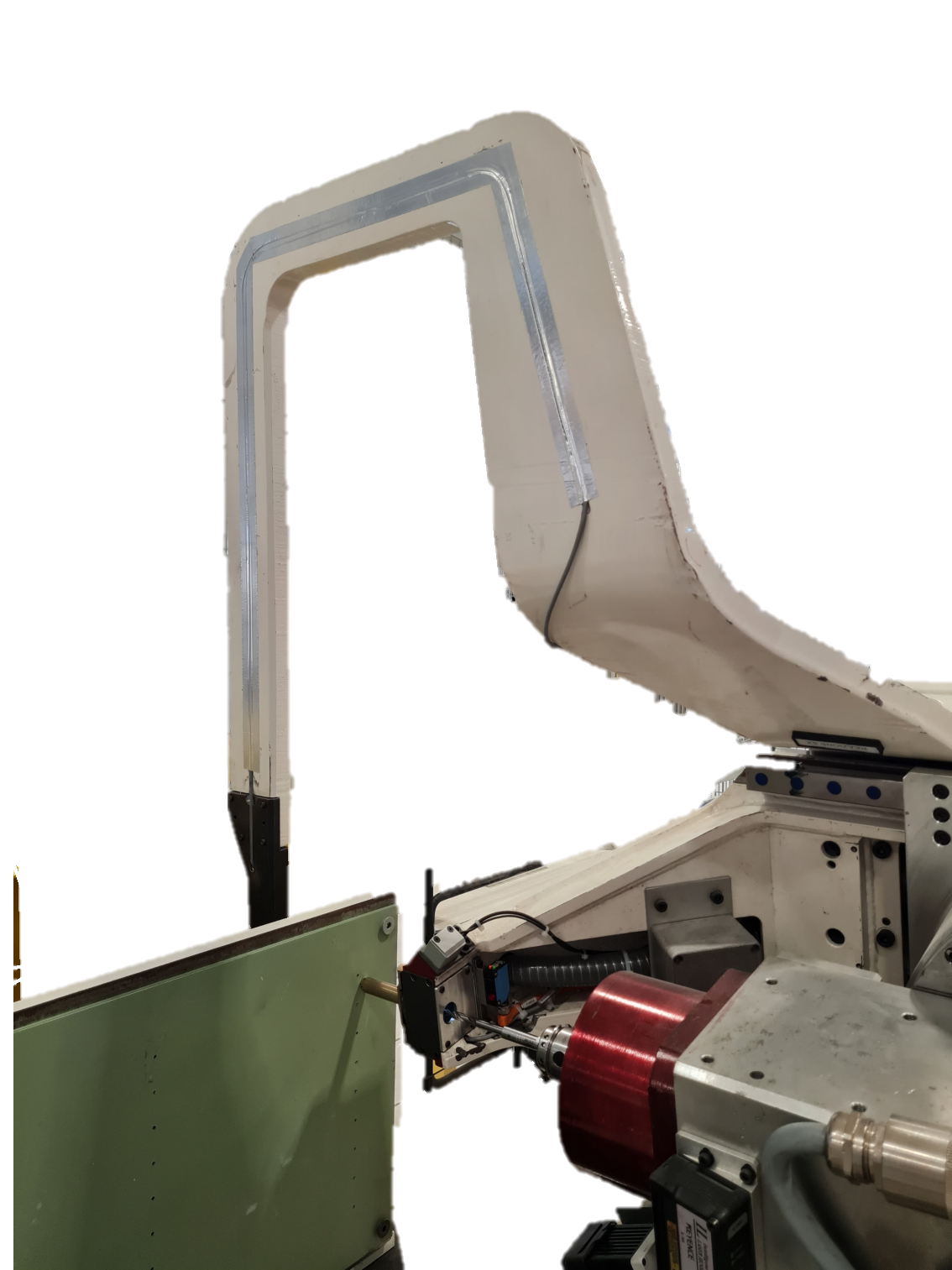

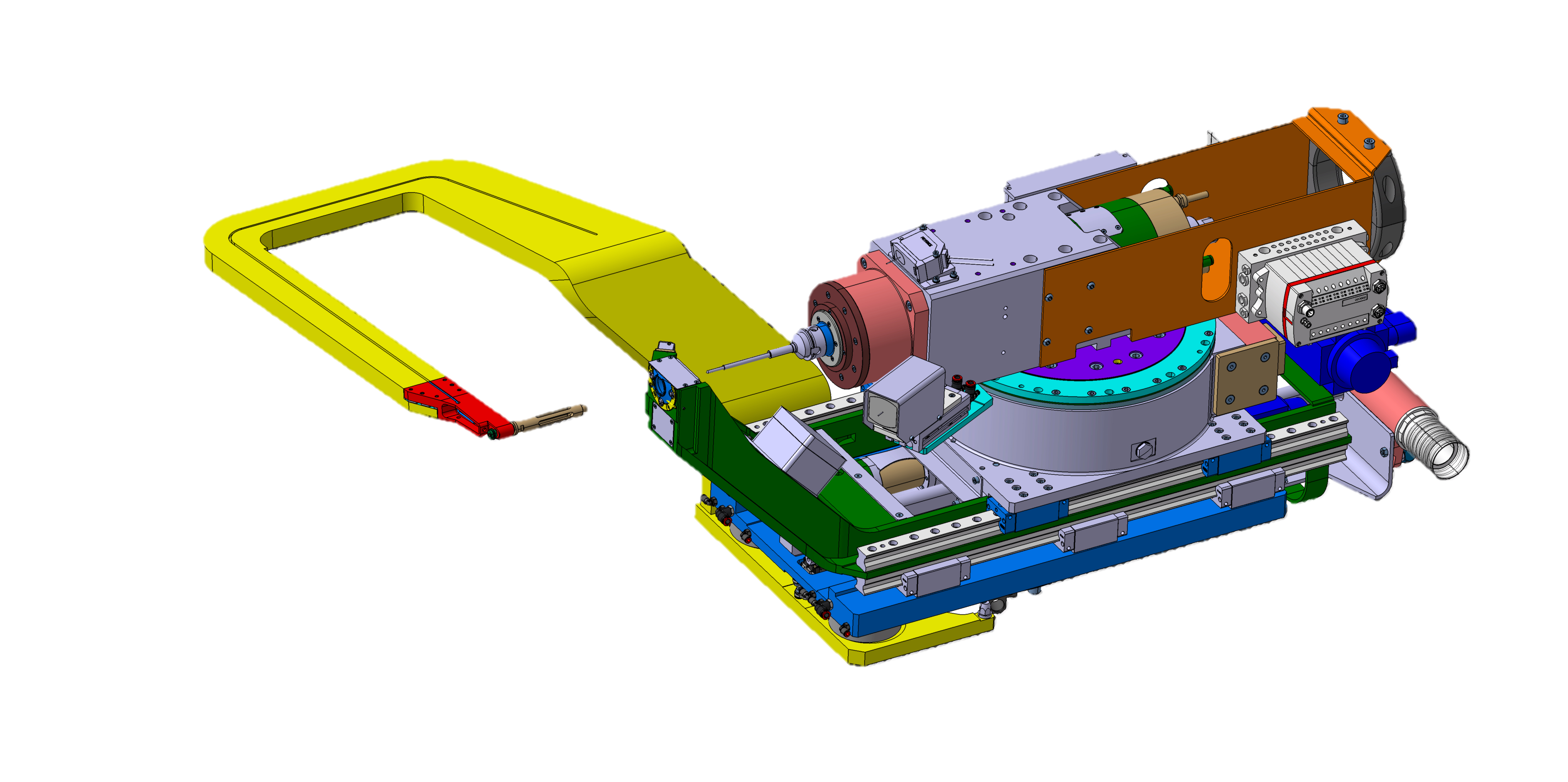

One-Up Drilling

Bisiach & Carrù end effectors are equipped with a specifically designed rear contrast, which allows to obtain a solid support at the back of the drilled stackup.

With this revolutionary technology, we are able to perform One-up drilling of very thin metal or composite stackups, avoiding the sheets to bend during the operation.

Moreover, the robot is able to automatically mount and unmount the contrast according to the drilling needs.