FUSELAGE

DRILLING & RIVETTING

Our company has a huge knowhow when we talk about operations on an aircraft fuselage. This comes out from an important presence in the field that led us to make a lot of research and development and strengthen our skills.

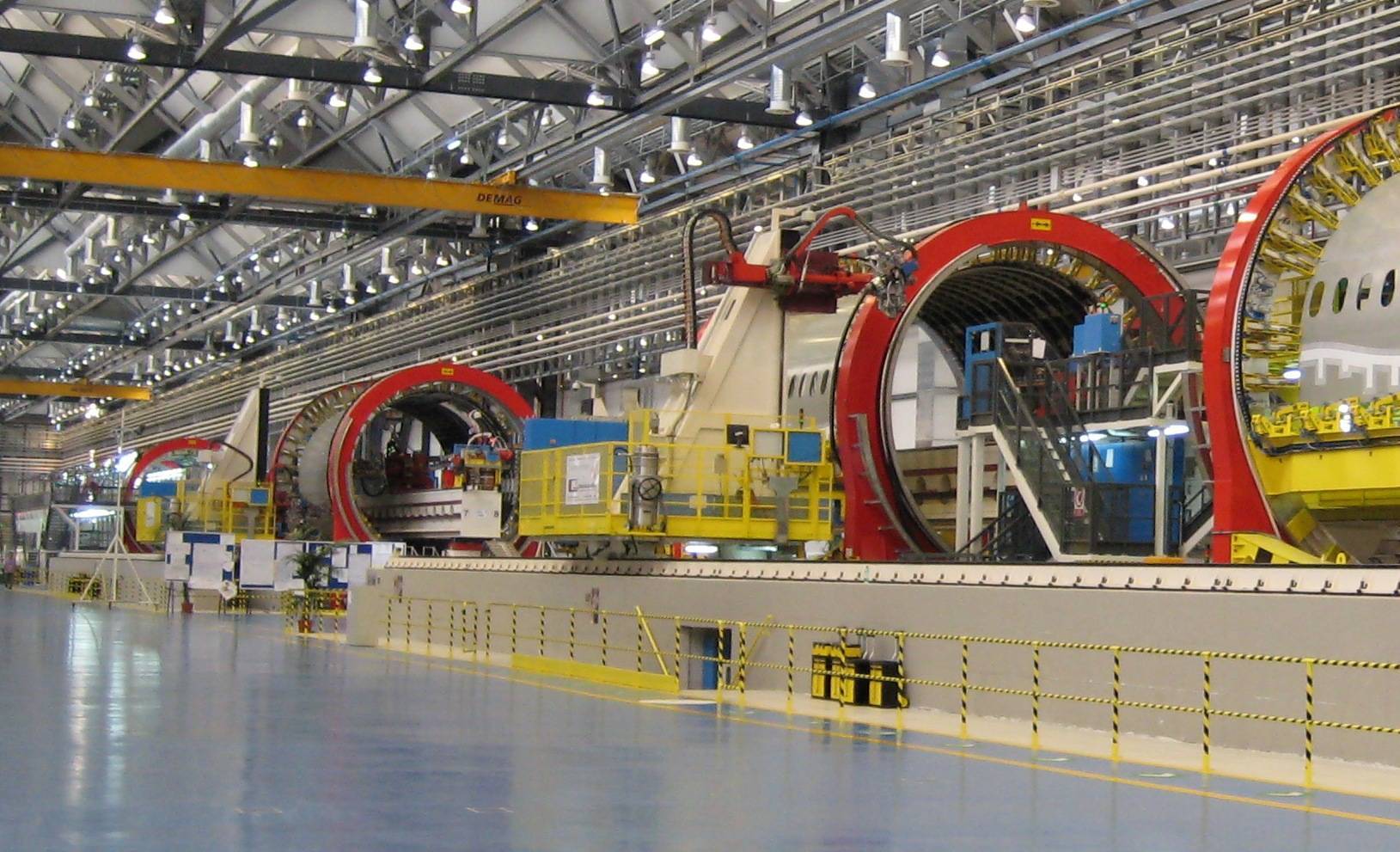

Bisiach & Carrù most important project was developed for the Boing 787 project, where our company was in charge to design the whole construction line of two central section of the fuselage.

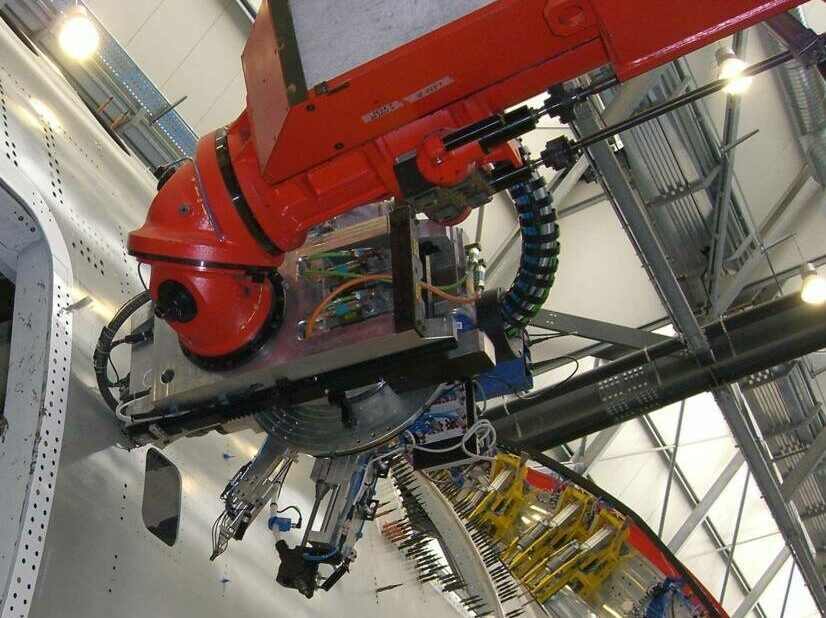

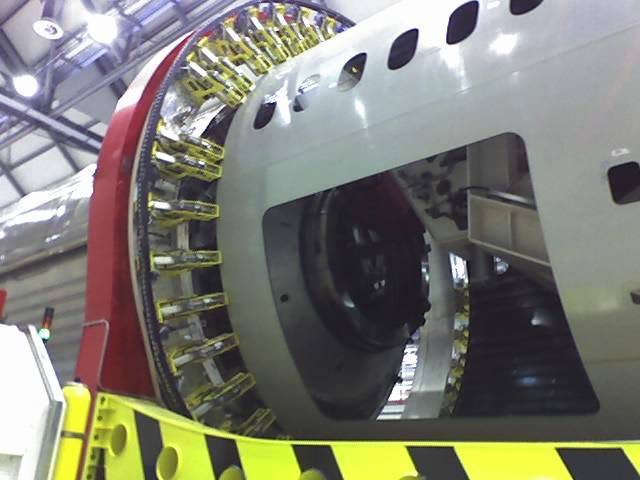

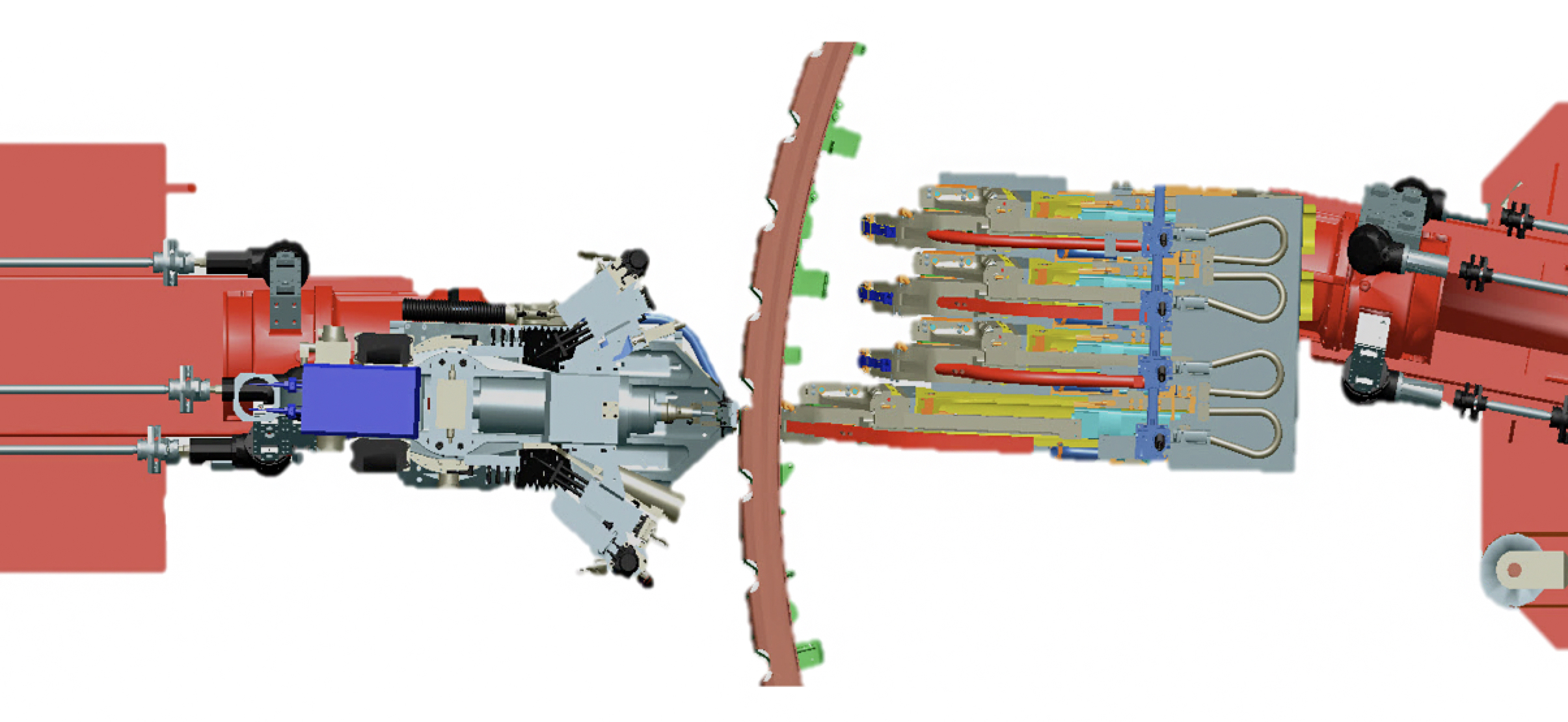

The drill and riveting part of the machining of the fuselage was realized by using two robots cooperating together. We implemented the one-up drilling on a closed fuselage by using an internal robot as a reaction and an external one as a driller. Then, the rivet was inserted from the outside and the collar from the inside, tearing off the rivet with the inner robot.

Our machines are so accurate that they can work in couples, approaching the element from two sides and aligning together without any visual contact. This capability allowed us to solve many technical challenges during the history of our company.