Rocket

Assembly

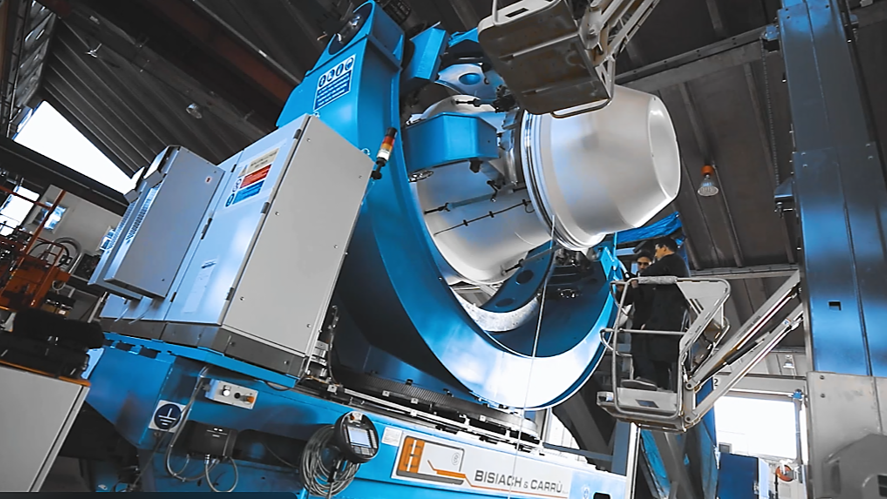

Automated Assembly Systems for Rocket Engines and Space Components

Bisiach & Carrù pioneers advanced robotic solutions for the automated assembly of rocket engines and space propulsion systems, supporting the growing space economy with high-precision, high-reliability manufacturing technologies.

Precision Engineering for Space Propulsion

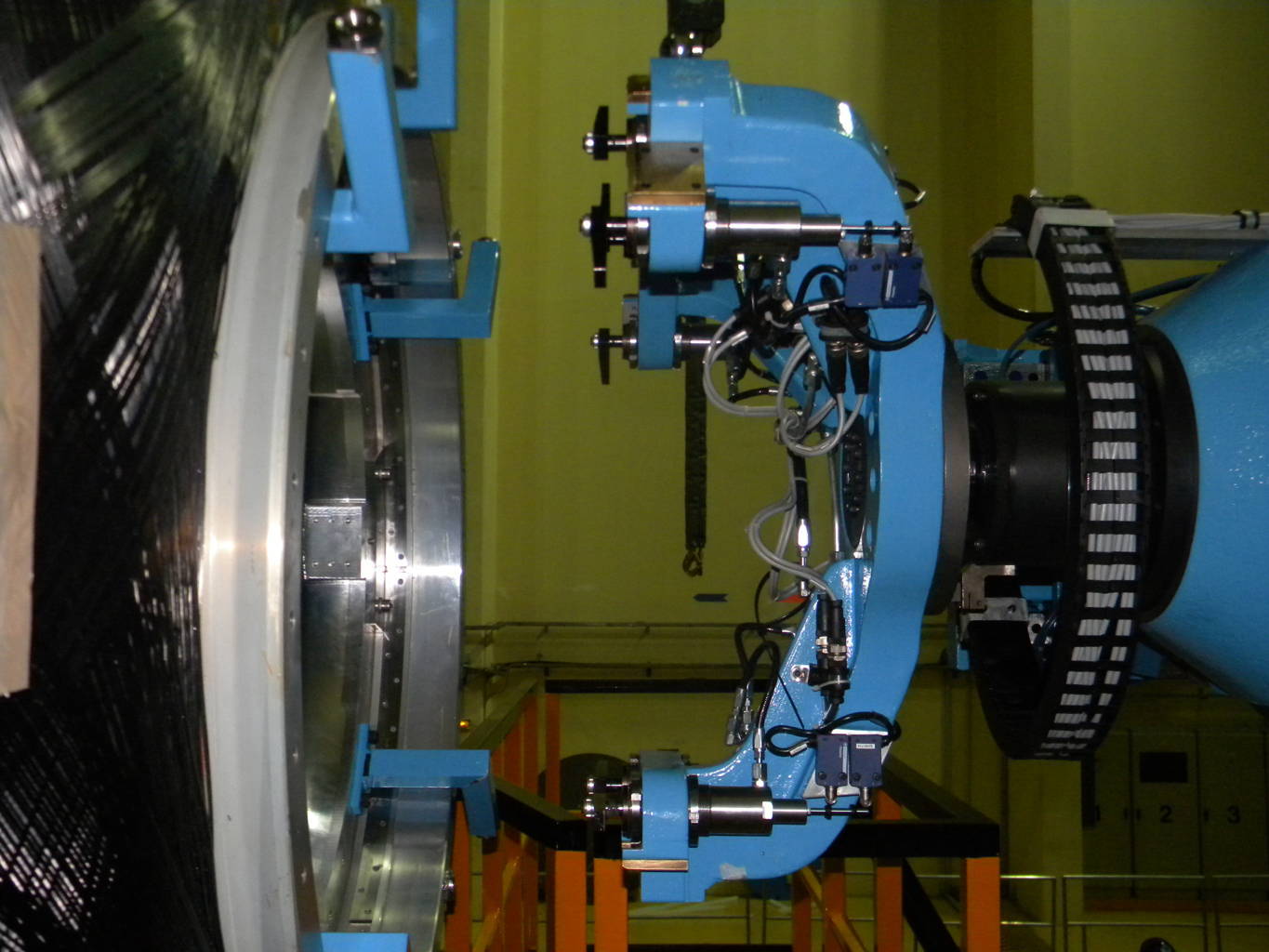

We developed a 7-axis Rocket Engine and Igniter Manipulator capable of assembling the engine and igniter of the Vega C (Avio) and Ariane 6 (ESA) rockets with unparalleled accuracy.

✔ Handling heavy aerospace components – The system can precisely manage 3,500 kg parts with a 3.5-meter diameter.

✔ Ultra-precise assembly – The engine is inserted into the rocket body with a clearance of just 0.05 mm, ensuring a perfect fit.

✔ Fully automated mobility – The entire manipulator is AGV-compatible, allowing it to move autonomously within the production plant.

Cutting-Edge Automation for the Space Industry

Bisiach & Carrù’s automated space assembly solutions enhance:

✔ Manufacturing efficiency – Reducing production time and human intervention.

✔ Component precision – Ensuring exact alignment for critical propulsion systems.

✔ Scalability – Adaptable for the assembly of future space propulsion technologies.

Why Choose Bisiach & Carrù for Space Component Assembly?

✔ Expertise in aerospace automation – Decades of experience in precision manufacturing.

✔ Bespoke robotic systems – Tailored to meet the stringent demands of the space industry.

✔ Seamless integration with AGVs – Enhancing smart factory automation.

With Bisiach & Carrù’s advanced robotic assembly technology, aerospace manufacturers can achieve unprecedented accuracy, efficiency, and scalability in rocket engine production and spacecraft component assembly.

Technical data:

- Rocket engine diameter: 3,5 m

- Assembly precision: 0,05 mm gap

- Engine weight: 3500 kg

- Rocket igniter diameter: 1,5 m

- Assembly precision: 0,05 mm gap

- Igniter weight: 1500 kg

- Generated force for integration: up to 8000 kg

- Manipulator weight: 32 ton

- Manipulator ring diameter: 4,2 m

- Manipulator height: 6,2 m